Die web-basierte Lösung für Ihre Produktion

Mit dem Production Throughput Inspector (PTI) erhalten Sie Einblicke in die Performance Ihrer Fertigungsprozesse.

PTI ermöglicht die Verfolgung von Materialflüssen in Echtzeit und die schnelle Identifizierung von unregelmäßigen Produktionsabläufen wie beispielsweise unplanmäßige Unterbrechungen. Dank der vom PTI gebotenen Transparenz kann ein geschlossener Optimierungsprozess etabliert und nachhaltig gesteuert werden, Prozessmuster und -metriken können analysiert und kontinuierlich überwacht werden.

Vorteile von PTI

Engpässe rechtzeitig bemerken und beheben

Optimierte Ressourcen-Auslastung

Verringerter Aufwand für Reports

Realistische Produktkalkulation & Lieferterminzusage

Prozessoptimierung auf Basis von Echtzeit-Daten

Automatische Taktzeit- und Stückzahl-Messung

Übersicht der Funktionen

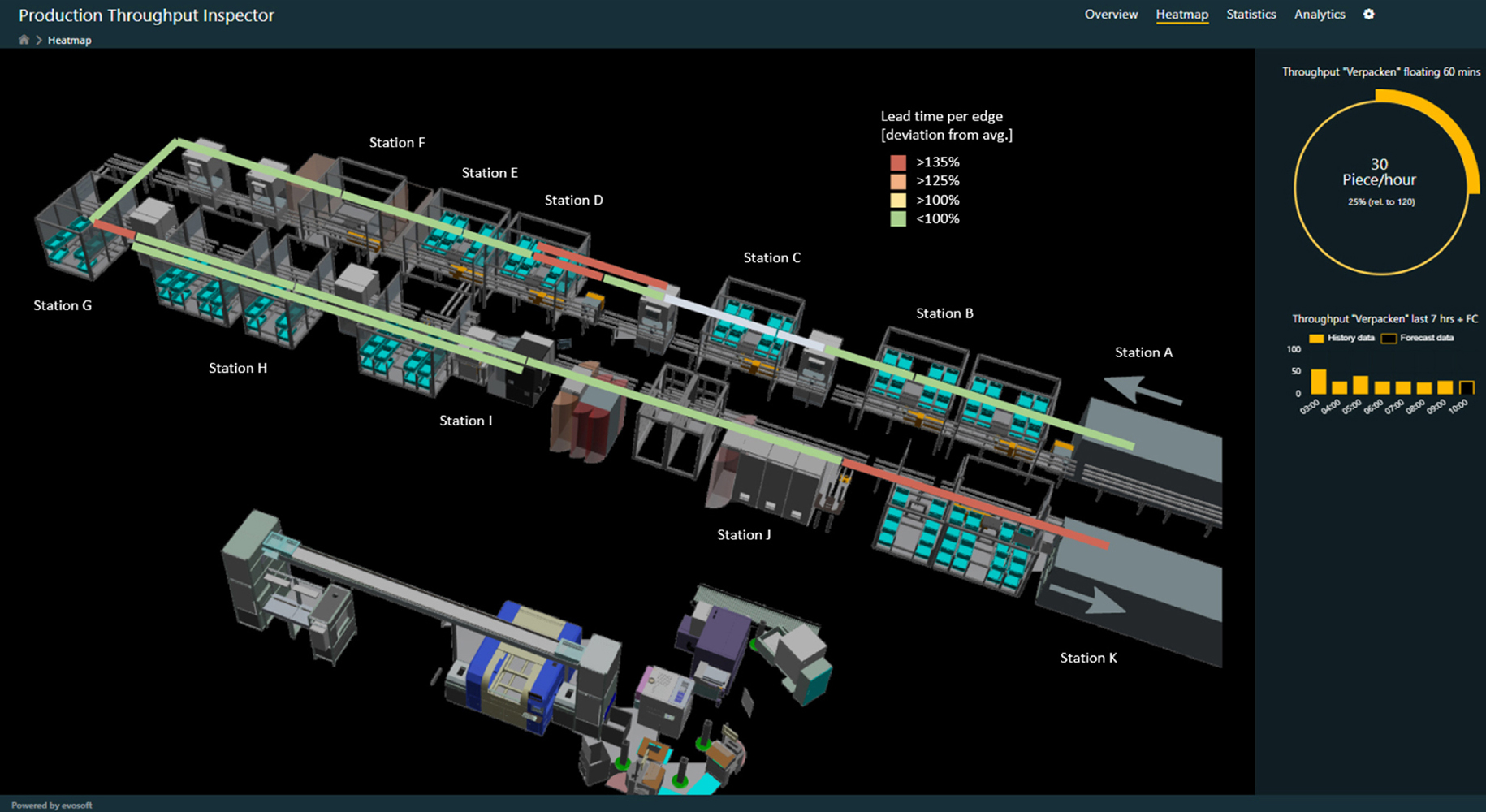

❙ Grafischer Gesamtüberblick des überwachten Produktionsbereichs oder der Anlage. Heatmap-Overlays visualisieren KPIs, wie z. B. die Durchlaufzeit des Materials auf bestimmten Bewegungspfaden. ❙ Widgets geben schnelles Feedback über die aktuelle Produktionssituation in Bezug auf bestimmte KPIs, wie z. B. den tatsächlichen Durchsatz oder die Zykluszeit. |  |

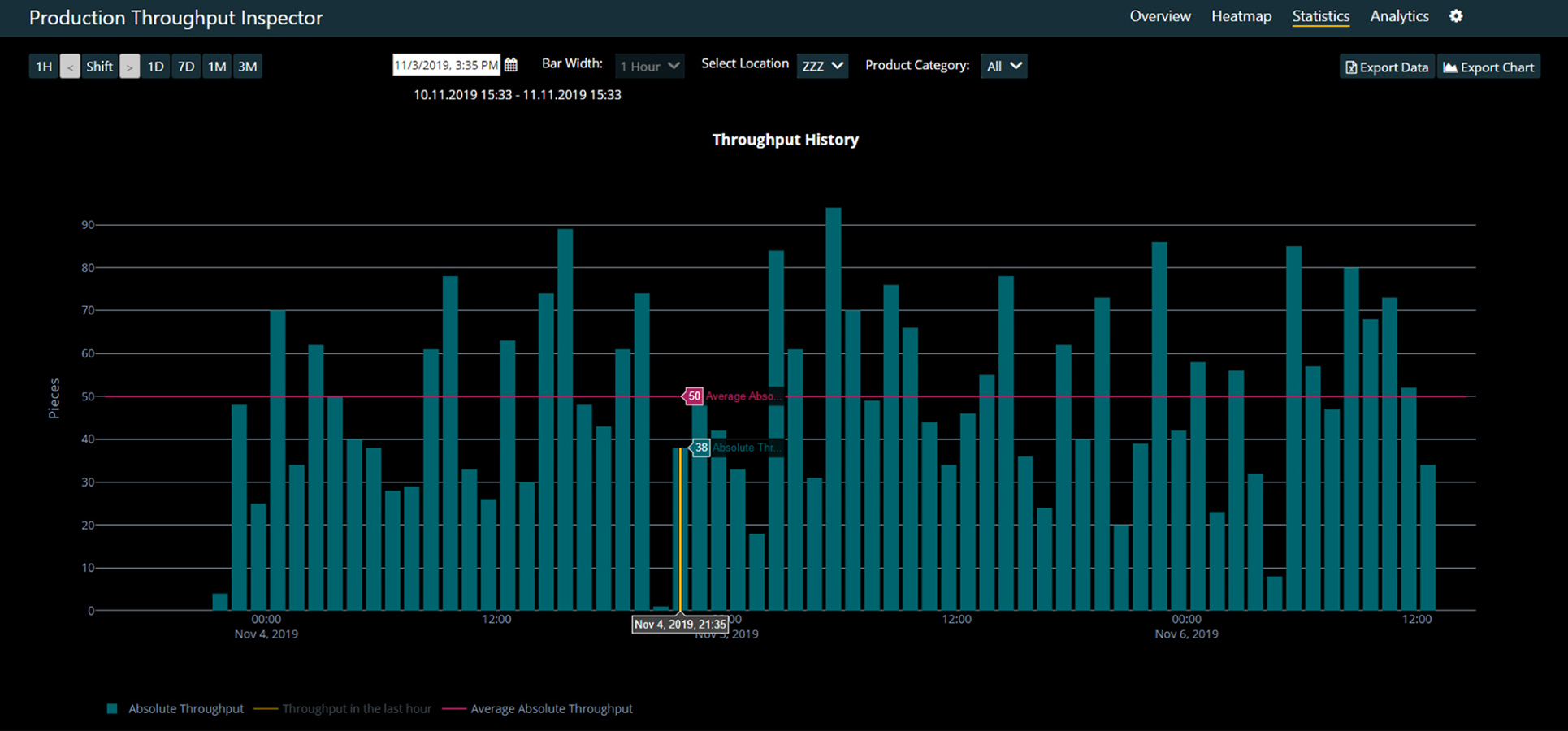

❙ Balkendiagramm für vergangene Durchsatzwerte, filterbar nach Zeitrahmen, Materialart, Arbeitsstation oder Produktionslinie. |  |

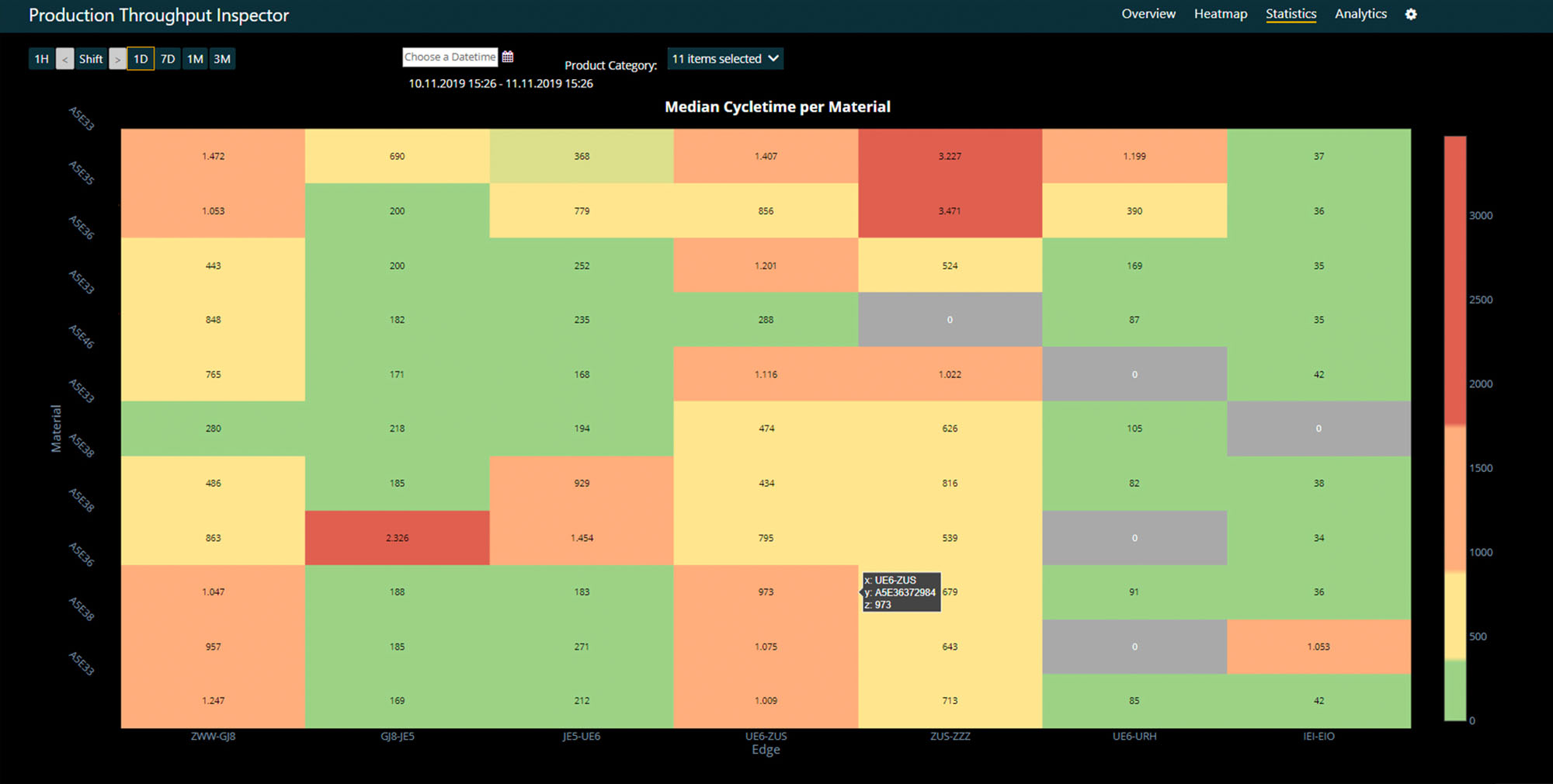

❙ „Heatmap“-Tabelle, die den Zeilenabgleich, d. h. die Zykluszeitverteilung aller verfolgten Artikel pro Materialart und Arbeitsplatz zeigt, filterbar nach Zeitrahmen und Materialart. |  |

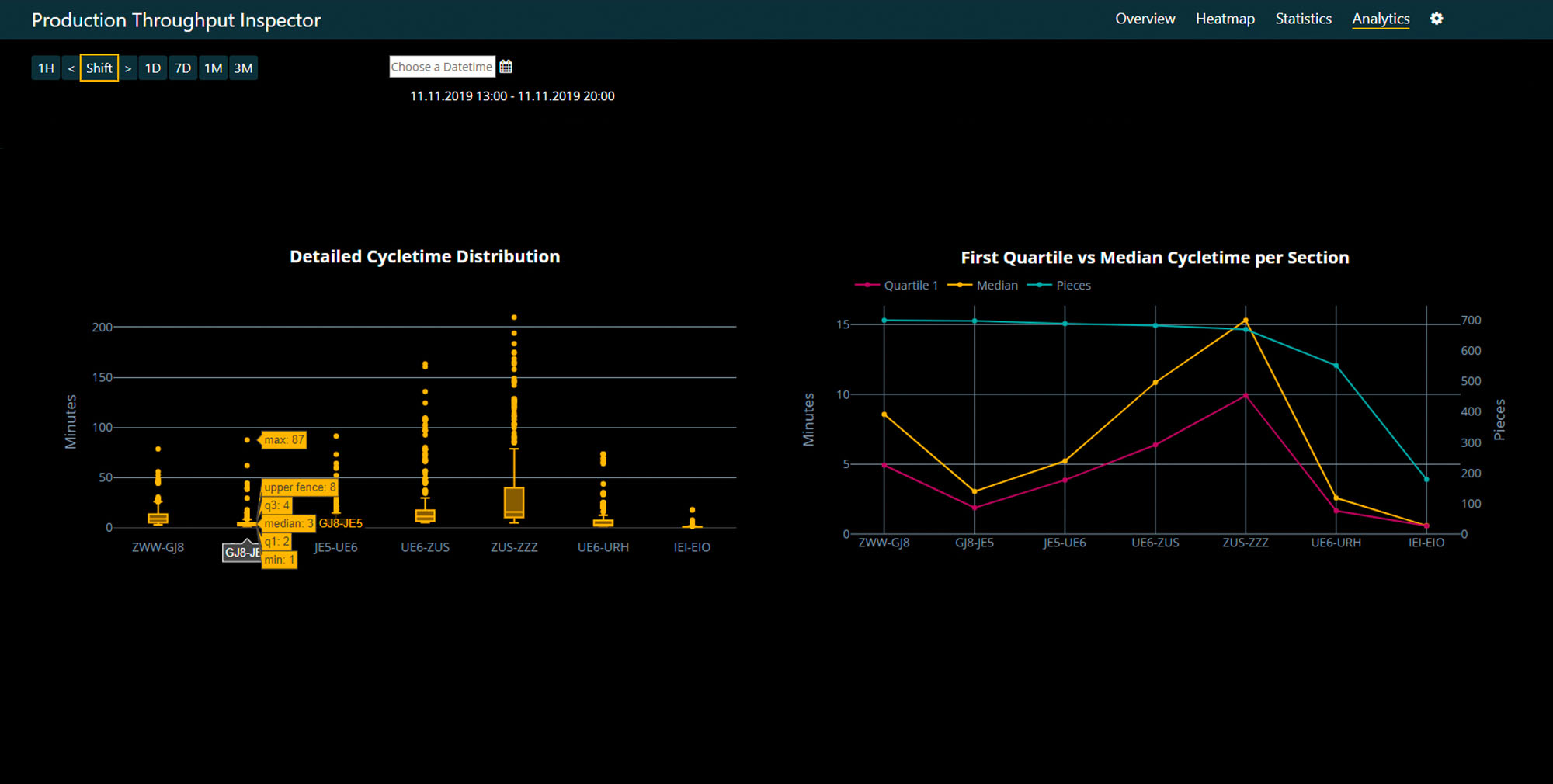

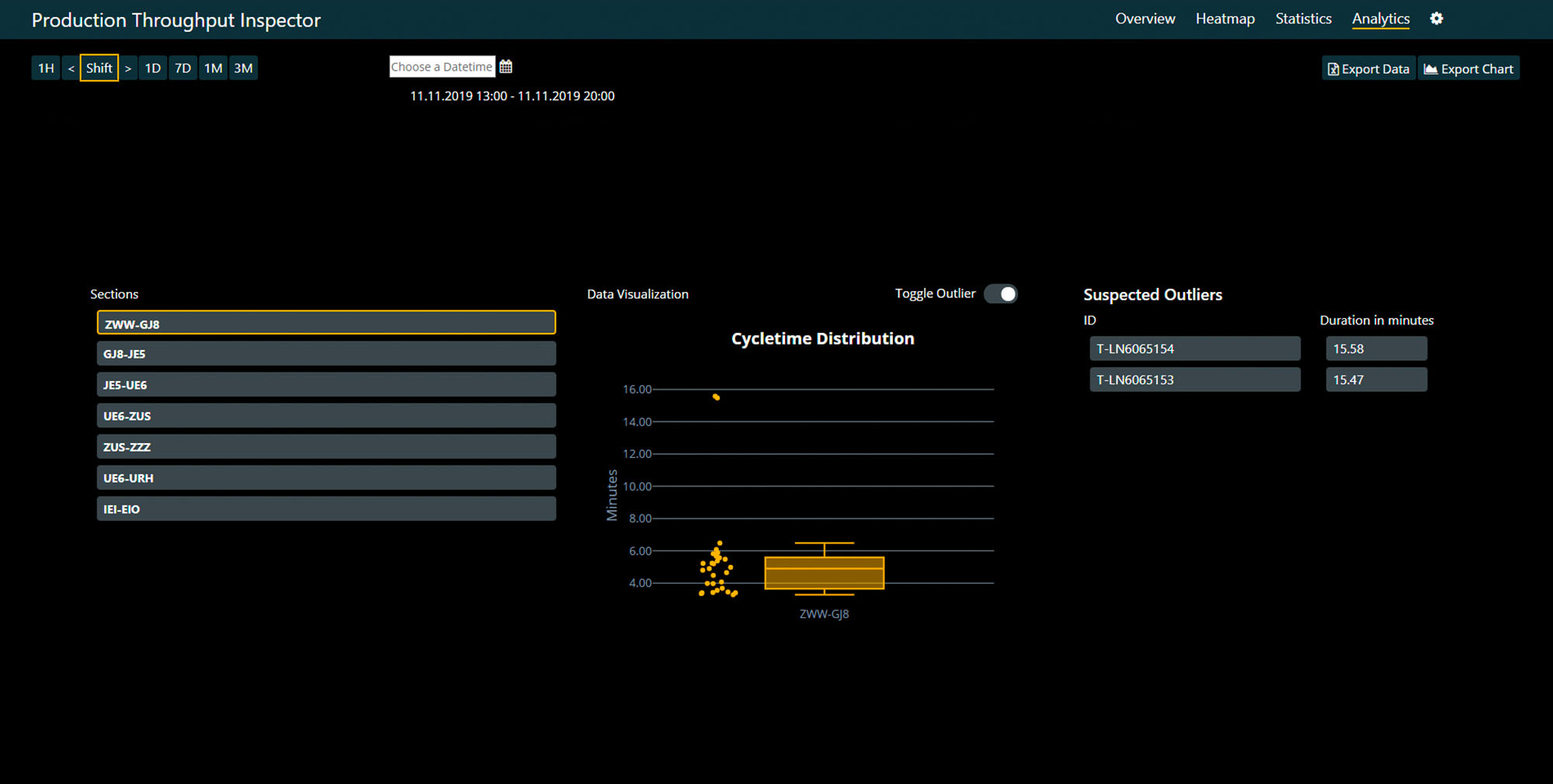

❙ Whisker-Plot zur Analyse von Engpässen für die Durchlaufzeitverteilung aller nachverfolgten Positionen. Filterbar nach Zeitrahmen, Materialart, Arbeitsstation oder Produktionslinie. |  |

❙ |  |

Einfache Integration von PTI

Wir wissen, dass die Zeit bis zur Integration eine Herausforderung bei Digitalisierungsprojekten ist: Bei unserer Lösung haben wir uns auf die einfache Implementierung in Ihre bestehende Infrastruktur und die Datenintegration über Standards wie OPC-UA und HTTP-APIs fokussiert.

Funktionsweise

Zeitmarken

Standort-Informationen

Daten zur Identifizierung beweglicher Objekte

Kontext-Informationen

Konfigurierbares Dashboard

Das PTI-Dashboard und die analytischen Ansichten verschiedener Daten bieten wertvolle Einblicke in die Prozess-Performance.

Beispiele für den Einsatz

von standortbezogenen Daten

- Prozesswege von Ressourcen und Materialflüssen

- Zykluszählung von Förderbändern und Matrizen

- Zeit- und standortbezogene KPIs

- Kontrolle von Gabelstaplern und Transportern

- Automatisierte fahrerlose Transportsysteme

- Verringerung der (manuellen) Materialtransporte

- Automatische Lager-/Wareneingangsbuchung

- Fortschritt der Fertigungs-/Transportaufträge

- Lokalisierung mit Geofences

Interessiert? Wir beraten sie gerne

Für weitere Informationen füllen Sie bitte das Kontaktformular aus.

Unsere Experten werden sich umgehend mit Ihnen in Verbindung setzen.