Our intelligent, AI-driven shop floor solutions aggregate data from all existing sources and visualise it in real time. Use it to overcome challenges in your company, achieve your quality goals and improve the utilisation of your assets.

Everything you need to get transparency in your production.

Advanced scheduling and planning for two production lines. Continuous control and optimisation in real time to increase productivity.

Integration of machine data, calculation of throughput ratios, identification of shortages in the production line

Reduction of set-up time, distribution of orders to two production lines, consideration of material availability

Dynamic warehouse size calculation, consideration of planned / actual figures, integration into existing system landscape

Calculation of the "product carbon footprint", data supply for the corresponding systems

Inventory optimisation, provision of key performance indicators

Order segmentation and order sequence planning for homogeneous machine utilisation to reduce idle times, increase productivity

Short-term and long-term staff workload planning based on required and available skills (skill matching)

Data-based order forecast considering external influences such as weather and seasonal events

Job planning for optimised utilisation of energy-intensive processes, reduction of downtimes and energy-intensive processes

The IIoT solution by evosoft

Get your free whitepaper now

Test now free of charge

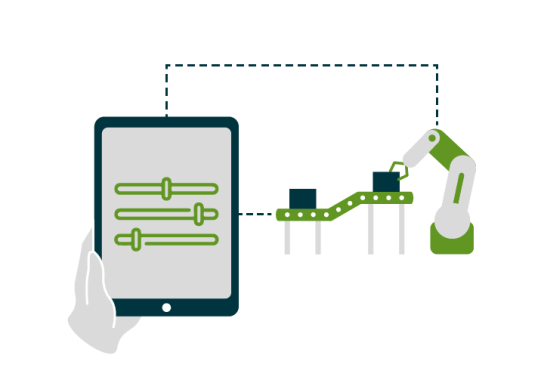

The intelligent AdvFlow solution optimises your production in real time. Different parameters can be prioritised via the configurator in order to adjust the optimisation targets according to your requirements.

With the configurator, you can easily adapt the optimisation to current business and production goals

“Digital solutions in production create opportunities for us to react more flexibly to customer wishes and generate productivity at the same time. AdvFlow helps us to optimally control production orders – algorithm-based and supported by live data from our machines”.

Franz Mende,

Factory Management Siemens equipment factory Amberg | Germany

Digitalised flow of information

Transparency and automation on the shop floor

Get an overall graphical overview of various data and analytical views of the monitored production area at any time, giving you valuable insights into your process performance and the opportunity for immediate optimisation.

Intelligent technology

Flexible adaptations in real time

Flexibly adapt your operating sequence to unscheduled challenges at any time. Dynamic optimisation allows your production orders to be carried out highly efficiently.

Production optimisation

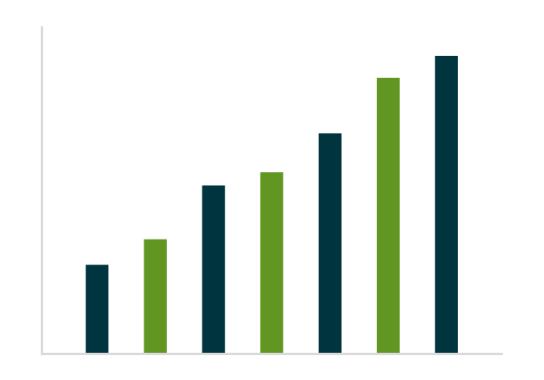

Measurable competitive advantages

We help you to uncover existing potential. Increase the productivity of your business so that you can meet constantly growing customer demands and stay one step ahead of the competition.

Get free trial now

Are you using the full potential in your production? Can you optimize your production dynamically and in real time? Get to know the evosoft solution platform and get access to the test environment – free of charge and without obligation.

Would you like to learn more? Talk to our experts.

All fields marked with * are mandatory

You will receive a tour of the digital IIoT solution. After reviewing your request, we will contact you for a personal demo appointment in the next few days.

You will learn how the software can support you in solving your manufacturing challenges.

Access to the test environment is free of charge and non-binding for you.

All fields with * are required

Digitization is changing the way companies work. Smart technologies such as the Internet of Things, artificial intelligence and data analytics are playing an increasingly central role in companies' manufacturing.

Learn about the added value through individual digitization use cases.

You will learn how the software can help you solve your manufacturing challenges.

Access to the whitepaper is free of charge and without obligation.